Introduction

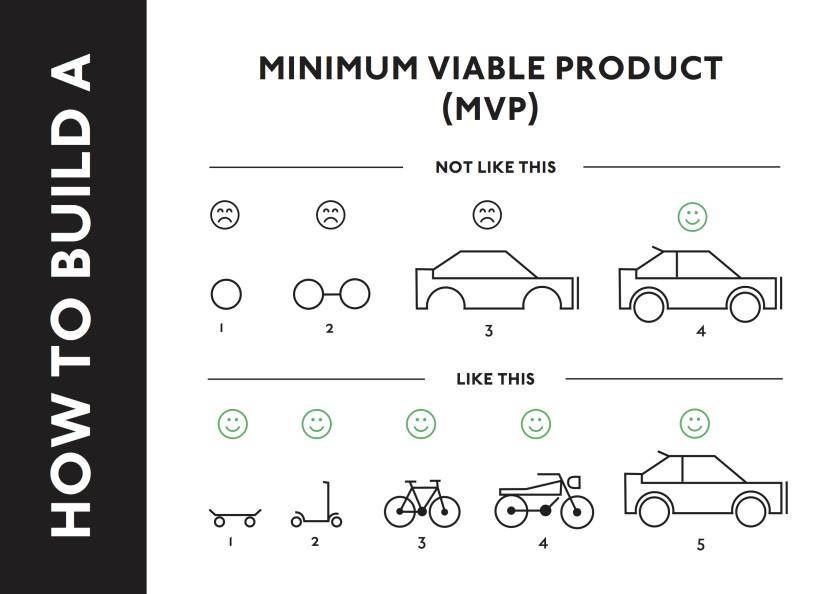

Consider this: If you were to build a mode of transportation, would you choose the first or the second method depicted in the image below?

First method: Design and manufacture various parts separately, only to assemble them into a usable car at the end.

Second method: Start with the simplest product, continuously iterate and improve, with each iteration of the product satisfying to a certain extent until the final expected effect is achieved.

The second method is the development of products using lean thinking, which is also the approach recommended by Nova.

What is Lean?

Lean is fundamentally about eliminating waste.

Currently, in many cases, it's not that products cannot be made, but rather that a lot of manpower, material resources, financial resources, and time are spent, and the end product is not what the user wants, which is the greatest waste.

As in the first method mentioned in the preface, the lack of user participation during the development process means that the success or failure of the product can only be tested at the end.

What if there are competitors with the same product?

What if the technology is outdated?

What if users do not accept it?

Usually, the likelihood of failure is quite high.

The lean approach is not to seek to be big and comprehensive, but to be small and refined, continuously improving the product, obtaining feedback from the market, and adjusting to approach the final product. The success or failure of the product can be tested and adjusted during the process.

Benefits of Lean

- Products are closer to user needs;

- Reduce redundant features, save costs;

- Can seize the market at the fastest speed;

- Product quality is steadily improved;

- The above benefits lead to project success, business growth, and increased income, etc.

The Broad Application of Lean

Toyota's Lean Production

Lean production originated from Toyota's Toyota Production System, used in automobile production.

Its guiding ideology is to optimize the overall production process, improve technology, streamline logistics, eliminate overproduction, eliminate ineffective labor and waste, effectively utilize resources, reduce costs, improve quality, and achieve the goal of maximizing output with the least input.

It is precisely the use of the lean production management philosophy that, after the 1973 oil crisis, Toyota not only achieved higher profits than other companies but also increased year by year, widening the gap with other companies. Lean has also been widely recognized and disseminated.

Lean in American TV Series Production

American TV series often start by shooting a pilot of dozens of minutes, which introduces the main character relationships, conflicts, and story background, and then invites dozens of viewers to participate in a small-scale preview, and then decides which modifications to make to the plot based on the feedback of the audience, whether to adjust the actors, and whether to invest in shooting. At the end of each season, the production side will also decide whether to cancel the series or order a new season based on viewership and audience opinions. This weekly shooting and seasonal broadcast model hands over all decision-making power to the audience, allowing for timely adjustments, reducing the investment and failure costs of the production side to the lowest, and is a typical lean entrepreneurial approach.

Lean at Nova

Lean is a core value of Nova. We have been practicing the lean methodology, expecting to eliminate waste fundamentally. At present, we have taken many measures, such as:

- Prototype Confirmation: Before we start developing features, we will first confirm the requirements and display methods through prototypes, which can reduce a lot of work waste caused by understanding deviations;

- Iterative Development: We recommend that customers prioritize the implementation of core functions, and after getting feedback from users, add functions, instead of adding all functions at the beginning; each iteration of the function is directly usable;

- Kanban Management: Our projects all use mature Kanban tools for task visualization management, which can effectively reduce management costs and improve efficiency.

- Reasonable Task Arrangement: Reasonable arrangement of the order of feature development to eliminate waste of idleness.

- Iterative Testing: Involve testers as early as possible in each iteration to nip most problems in the bud and reduce waste caused by problem fixing;

- Reduce Semi-finished Products: Unfinished tasks belong to semi-finished products. An easy-to-understand semi-finished product state is a few intermediate states in the JIRA Kanban, such as "In Development", "Waiting for Testing". If there is a backlog of "Waiting for Testing" tasks, it also means that progress and quality may be out of control, so the company requires testers to intervene as early as possible, to accept tasks as early as possible, and to reduce risks.

- Use Mature Frameworks: Don't spend energy redesigning the wheel. Nova has accumulated open source frameworks, and many functions have mature solutions, which can save a lot of workload and time, and also reduce the probability of errors.

Customer Collaboration

If you recognize lean, you can cooperate with Nova's work from the following aspects to achieve a win-win cooperation:

- Screen Core Functions: Assist Nova in finding the core functions of the project. Nova suggests that functions that are not very important can be postponed or put in the second phase;

- Participate in Prototype Confirmation: The prototype is a low-cost requirement confirmation method. Confirming it clearly before development can reduce many problems;

- Do not overly pursue the perfection of design: Many problems are exposed during use. No matter how much energy is spent on design in the early stage, it may be overturned later;

- Do not overly pursue the novelty of technology: The latest technology is most of the time not the most suitable technology. New technology is usually immature and may have various unexpected problems;

- Participate in Testing as Soon as Possible: Participate in iterative testing as early as possible, provide suggestions; you can also promote the final user to participate in the test.

Failure Cases

Case One: A Client's Case

In early 2015, Nova undertook a foreign project, and the client's business requirements were very large, with many features and some features that needed to overcome technical challenges. The client insisted on completing all functions before going online.

We formed a project team and spent 2 years implementing all functions. However, it was later understood that although the project had complete functions, there were no users after going online, and it did not achieve the expected effect. It was stopped only 2 months after going online.

Case Two: Webvan Case

Webvan is a very advanced concept of a fresh fruit and vegetable company, with online transactions and offline transportation, with its own storage and distribution system, and delivers fresh groceries.

The company was established in December 1996, and the first investment from venture capital was put in in 1997. After two years of closed research and development, using high-tech technology, the first automated storage system was developed. One month after going online, the first order was accepted.

But because the early stage was too idealistic, the designed system did not match the actual situation, such as: the expected 8000 orders per day, but the actual 1000 or so, which led to a great waste of fixed costs.

The ultimate fate was that after running for two years, it was declared bankrupt.

Success Cases

Case One: The Development History of WeChat

WeChat, as a product, has been integrated into our lives and is gradually influencing our way of life.

But did you know that its initial positioning was just a notification tool?

When a contact sends you a message, it notifies you;

When there are new entries in QQ mailbox or QQ offline messages, it notifies you;

When you receive a private message on Tencent Weibo, it notifies you.

The initial simplicity of the function accelerated the launch and update speed of WeChat. WeChat only released 15 versions in the first year, continuously collecting user feedback for functional adjustments from these versions.

From the following main version history, we can see that the widely used circle of friends function did not appear until WeChat 4.0 version.

Main Version Release Date Main Features WeChat 1.0 January 21, 2011 Instant messaging, photo sharing, change avatar WeChat 2.0 May 18, 2011 Voice messages, first official version WeChat 2.5 August 3, 2011 People nearby, send videos WeChat 3.0 October 14, 2011 Bottle message, shake WeChat 3.6 February 7, 2012 Group assistant, Tencent News, QQ mail WeChat 4.0 May 25, 2012 Circle of friends, open interface WeChat 4.2 August 17, 2012 Video, web version, circle of friends comments WeChat 4.5 February 6, 2013 Intern monologue, location navigation WeChat 5.0 August 9,2013 Sticker shop, Scan and Pay, WeChat Pay, voice recognition

WeChat 5.4 September 9, 2014 Enhanced search function, face-to-face payment

WeChat 6.0 October 14, 2014 Short video feature, card package

WeChat 6.2 May 26, 2015 WeChat Sports, open emoji platform

Case Two: Amazon Fresh O2O

Six years after Webvan's bankruptcy, in 2007, a company quietly entered the online fresh produce sales industry, which is Amazon. Amazon established an online fresh produce sales department called Fresh, and Fresh adopted a "Lean Startup" approach.

Amazon is distributed globally, but when Amazon entered this industry in 2007, it only chose a single city - Seattle. Why choose Seattle? Because Seattle ranks first in the acceptance of new things. Fresh did not cover the entire city either, but chose a few neighborhoods in Seattle, and the selected neighborhoods also have their own characteristics. In the early stage, it only implemented simple functions to solve the most painful pain points for users, and then obtained feedback from users.

After testing this model for 5 years, Amazon started to enter the second city - Los Angeles, and also only chose a few neighborhoods, not the entire city.

Amazon's approach is a typical lean methodology: with low cost and fast speed, starting from a small aspect, continuously trying and fixing errors, and then expanding until success is achieved.

More Lean Knowledge

Lean Startup Lean Startup originated from the Internet industry and is a new model of software development. Its main tools are "Minimum Viable Product", "Customer Feedback", and "Rapid Iteration".

Lean Canvas The Lean Startup Canvas is an efficient action pointer and battle map for early entrepreneurs. It has been used by many start-up companies in Silicon Valley. The Lean Startup Canvas includes ten parts:

Customer insights, pain/need mining, product/solution design, unique value proposition, scarce competitive advantage, customer contact channels, profit model/revenue sources, cost structure, strategic goals, action plan

These ten aspects of the Lean Startup Canvas are the key points that early entrepreneurs need to focus on, and are also the only nodes that need to be focused on. This allows entrepreneurs to focus more, making entrepreneurship based on a solid foundation, and improving the probability of entrepreneurial success.

Lean Production Lean Production, referred to as "Lean", is a management philosophy derived from the Toyota Production System.

Lean production is a production management method that adapts quickly to the ever-changing user needs through changes in system structure, personnel organization, operation mode, and market supply and demand. It can eliminate all useless and redundant things in the production process, ultimately achieving the best results in all aspects of production, including market supply and demand. Different from the traditional mass production method, its characteristics are "multi-variety" and "small batch".

Lean Development Similar to the concept of lean manufacturing principles, lean development can also be summarized as the following seven principles:

Respect the front-line personnel People working on the front line know the actual situation best. They know what is happening now and know the best way to deal with the current situation;

Eliminate waste If an activity can be skipped or the final result can be achieved without these activities, then it is waste.

Code that is made during the development process and is ultimately abandoned is waste. Additional processing and features that customers do not use often are waste. Waiting for other activities, teams, and processing is waste. Defects and low quality are waste. Excessive management that does not produce actual value is also waste. Methods based on value streams are used to identify waste. The second step is to identify the root of waste and eliminate it. Continuously eliminate waste until some processes and steps that even seem essential are removed.

Enhance learning Using short iterative cycles (each iteration should include refactoring and integration testing) can accelerate the learning process. Enhance feedback with the help of customers through short feedback meetings. Through these short feedback meetings, customer representatives and development teams will find more of the main problems and possible solutions that will be encountered in further development. Based on the developed prototype, customers can better understand their own needs, and developers can also understand how to better meet customer needs.

Delay decisions as much as possible Because software development usually has a certain degree of uncertainty, methods based on multiple choices can achieve better results. Delay decisions as much as possible until they can be made based on facts rather than uncertain assumptions and predictions. The more complex the system, the stronger the system's ability to accommodate changes should be, giving it the ability to delay important and key decisions.

Embed quality Quality is produced in the process; If the quality of the output can be guaranteed at every stage of the development process, the quality of the final product can be achieved at the lowest cost; Ensuring quality in the process can greatly reduce waste, and quality is part of the process.

Fast delivery The benefits of fast delivery are countless, such as allowing customers to get the value of the product earlier and enabling the product to enter the market faster;

Overall optimization Local optimization, if it cannot bring overall improvement, is worthless; Construct a complete product.